Top 10 Container and Packaging Supply Tips You Must Know?

In the dynamic world of logistics, understanding container and packaging supply is crucial. The global packaging market is projected to reach USD 1 trillion by 2024. This underscores the importance of optimizing supply chains. Inadequate supply strategies can lead to delays and increased costs. Many companies still struggle with managing excess inventory, which can tie up valuable resources.

Sustainability is another key factor influencing container and packaging supply. Reports show that 74% of consumers prefer eco-friendly packaging. This preference impacts purchasing decisions significantly. Companies must innovate to meet these demands while balancing cost and functionality. Some businesses, however, have yet to adapt their strategies accordingly, risking their market position.

The competition continues to intensify. Over 50% of logistics providers are investing in advanced technologies. These technologies enhance tracking and inventory efficiency. Yet, some companies remain hesitant to invest, leading to missed opportunities for growth. Embracing change can be challenging, but it is necessary for survival in the ever-evolving marketplace.

Essential Considerations for Choosing the Right Packaging Materials

Choosing the right packaging materials can be challenging. Various factors affect your decision. For instance, consider the weight and fragility of your product. Heavier items require sturdier packaging. Delicate products need cushioning to prevent damage.

Sustainability is another key aspect. Many consumers prefer eco-friendly options. Cardboard and biodegradable plastics are good choices. However, balancing cost with sustainability can feel daunting. Sometimes, these options can be more expensive. You may have to compromise on other areas.

Another important consideration is the size of your packaging. Too large can inflate shipping costs. Too small may not protect your product adequately. Testing your packaging design can save future headaches. Don't hesitate to reevaluate your choices as needed. Your initial decisions might not always be the best. Innovating your packaging can lead to better customer satisfaction and reduced waste.

Understanding Different Types of Containers and Their Applications

Understanding the various types of containers is essential for effective packaging. Different materials serve different purposes. For example, glass containers are excellent for preserving flavor and freshness. They are heavy and fragile. Plastic options are lightweight but can lack durability.

One crucial tip is to know the right container for your product. Using the wrong material may impact shelf life. For food items, consider biodegradable options. They are eco-friendly and gaining popularity. Another tip is to prioritize sealing methods. Poor sealing can lead to spoilage or leakage.

Consider the size and shape of containers too. A well-fitted container minimizes waste and reduces costs. However, larger containers can be more appealing visually. Balancing aesthetics with functionality can be tricky. Always test containers before large-scale use. This helps in identifying potential issues. Remember, the best container is one that meets your specific needs effectively.

Best Practices for Ensuring Packaging Sustainability and Eco-Friendliness

Sustainability in packaging is more crucial than ever. Brands must prioritize eco-friendly materials. This choice starts with understanding the impact of plastic. A significant amount of plastic waste harms our oceans. Many materials are recyclable or biodegradable. Choosing these options can ease environmental burdens.

Consider using minimalistic packaging designs. Overly elaborate designs waste resources. A simple box often suffices. It’s practical and reduces waste. Additionally, using recycled materials can enhance your brand's green image. It shows a commitment to the planet, encouraging customer loyalty.

Understand the importance of consumer education. Not everyone knows how to dispose of packaging properly. Clear labeling can help. It’s a small step but can lead to significant change. Continuous improvement is essential. Companies must regularly re-evaluate their practices. Are they truly sustainable, or just meeting trends? Reflecting on these questions is vital for progress.

Tips for Cost-Effective Sourcing of Packaging Supplies

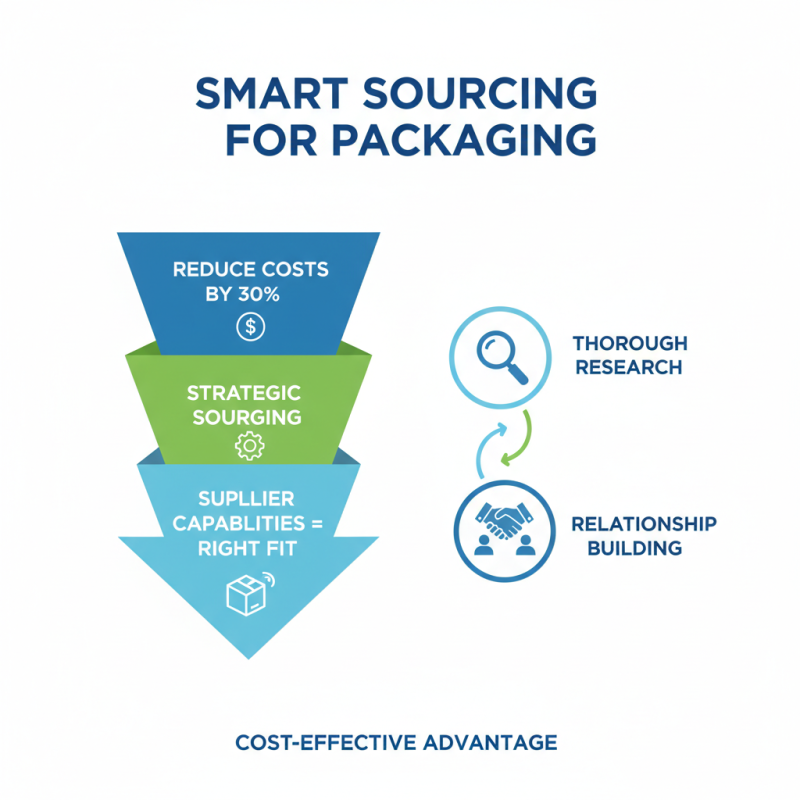

Cost-effective sourcing is critical in the packaging industry. Recent data shows that companies can reduce costs by up to 30% with strategic sourcing. Understanding supplier capabilities helps businesses find the right fit for their needs. This requires thorough research and relationship-building.

Analysis of packaging trends reveals a shift towards sustainable materials. For instance, 74% of consumers prefer eco-friendly packaging. This preference drives companies to seek suppliers who can provide recyclable or biodegradable options. Those who adapt can meet consumer demands and reduce costs simultaneously.

Many businesses overlook the impact of bulk purchasing. Data indicates purchasing in larger quantities can lower per-unit costs. However, companies must balance inventory levels to avoid overstock. Excess inventory can lead to waste. Regularly reviewing stock and supplier agreements helps optimize spending. Adjustments based on sales forecasts can improve profitability.

The Importance of Proper Labeling and Compliance in Packaging

Proper labeling and compliance are crucial in packaging. Many businesses overlook these aspects, which can lead to costly mistakes. Clear labels ensure that customers understand the product inside. They provide essential information about ingredients, instructions, and warnings. A simple oversight can lead to confusion or even harm.

Compliance with regulations is not just a legal requirement; it's a responsibility. Packages must meet industry standards. This includes including necessary certifications or seals. Sometimes, businesses assume they know the rules, but regulations may change. Failing to stay updated could invite penalties. It’s worth noting that even attractive packaging loses value without proper labels.

Thinking critically about labeling practices can reveal areas for improvement. Using fonts that are difficult to read is a common issue. Overly complex language can alienate customers. Keeping it simple enhances understanding. Engaging with your audience can provide insights into their needs. Regularly reviewing your packaging can help ensure compliance and clarity. Ensuring labels are as effective as possible requires ongoing effort and reflection.

Related Posts

-

Exploring Sustainable Innovations in Container and Packaging Supply for a Greener Future

-

Innovative Container and Packaging Solutions Revolutionizing Sustainable Practices

-

10 Essential Tips for Choosing the Right Cosmetic Jars for Your Products?

-

What is Amber Glass Jars and Why Are They Popular for Storage

-

Top 10 Benefits of Using Amber Glass Bottles for Storage?

-

Innovative Designs in Cosmetic Containers Elevating Your Beauty Brand Aesthetic