What is a Geomembrane Welding Machine and How Does It Work?

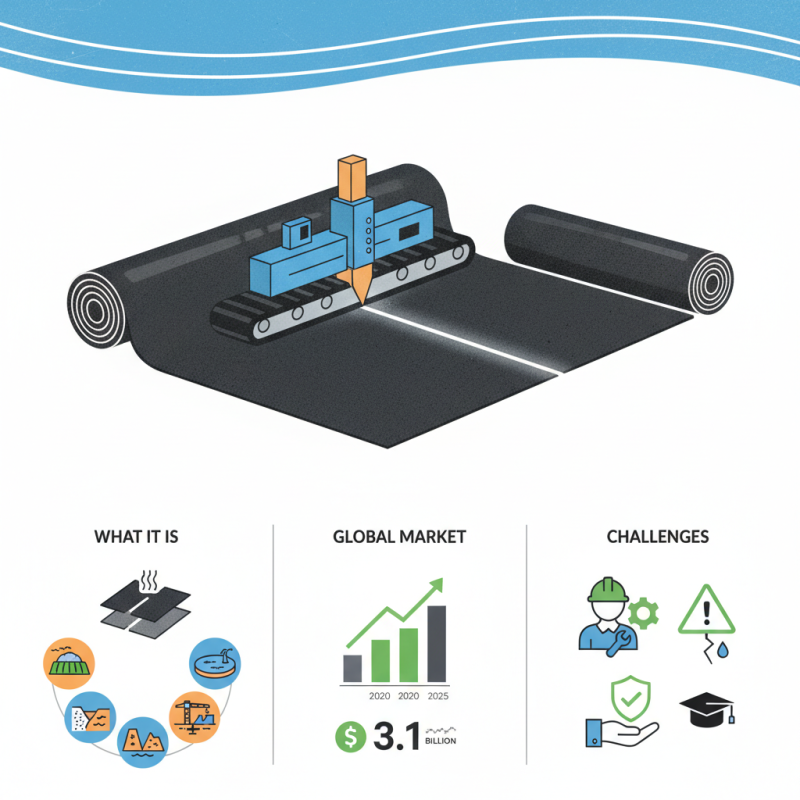

In construction and environmental engineering, the geomembrane welding machine plays a critical role in ensuring the integrity of containment systems. This machine is essential for creating robust seals in geomembrane applications. According to industry reports, the global geomembrane market is projected to reach $3.1 billion by 2025, indicating a growing demand for reliable welding techniques.

The geomembrane welding machine uses heat or pressure to join materials effectively. Its applications span from landfills to water reservoirs, showcasing its versatility. The quality of welds directly influences system performance and longevity. Studies indicate that improper welding can lead to significant failures in containment systems, risking environmental safety and financial loss.

Yet, the industry faces challenges. Operators must have proper training to use these machines correctly. Mistakes in the welding process can result in leaks, which can undermine project objectives. As demand increases, ensuring skilled personnel remains a priority to uphold quality standards in geomembrane welding.

What is a Geomembrane Welding Machine?

A geomembrane welding machine is essential for joining geomembrane materials. These machines are designed to create strong seams, ensuring waterproof integrity. They are widely used in construction and environmental applications. The global geomembrane market was valued at approximately $2.8 billion in 2022, showing the growing importance of these materials.

The working principle of a geomembrane welding machine involves heat or friction. For instance, hot wedge machines use a heated wedge to melt the edges of geomembranes. The fused materials create a durable bond. The machine's precision can significantly affect project outcomes. However, achieving consistent quality requires skilled operators.

Flaws can happen during the welding process. Temperature inconsistencies or speed variations might lead to weak seams. Reports indicate that improper welding can undermine the longevity of geomembrane installations. Continuous training and quality checks are vital. The industry must address these challenges to enhance reliability.

Key Components of a Geomembrane Welding Machine

A geomembrane welding machine is essential for projects that require waterproof barriers. It combines heat and pressure to seal geomembrane materials effectively. Understanding its key components is crucial for optimal usage.

The heating element serves as the core of the machine. It generates the necessary temperature for welding. Proper calibration is vital. Too high a temperature can damage the material. Too low, and the seal may fail. This requires careful attention during setup.

The pressure rollers apply consistent force to ensure a strong bond. They help maintain contact between surfaces. However, too much pressure can lead to wrinkles. It’s important to strike the right balance.

Another component is the control panel. It allows operators to adjust settings easily. Familiarity with the controls is essential. Poor understanding can cause mistakes.

Tips: Regular maintenance of the welding machine enhances its lifespan. Check all components often. Understanding the equipment ensures better outcomes. Don't hesitate to seek guidance if unsure about any aspect.

Principles of Geomembrane Welding Technology

Geomembrane welding technology is essential for creating waterproof barriers in various applications. This process involves the use of specialized machines that generate heat, enabling the fusion of geomembrane materials. High-frequency electromagnetic energy or hot air is typically employed for this purpose. The right temperature is critical for achieving a secure weld without damaging the material.

The operation of a geomembrane welding machine relies on precision and control. The welding head moves along the joint, applying consistent pressure and temperature. One common method is extrusion welding, where molten material is introduced to the joint for added strength. However, achieving the perfect weld can be challenging. Variations in temperature or speed can lead to weak spots. Proper training and experience are vital for operators.

Each project presents unique challenges. Different materials and environmental conditions can affect welding results. Monitoring equipment is essential to ensure quality. Some operators may overlook small details, leading to failures. Reflection and continuous improvement are necessary in this field.

What is a Geomembrane Welding Machine and How Does It Work?

| Dimension | Description |

|---|---|

| Welding Method | Hot Wedge, Extrusion, and Liner Welding |

| Temperature Range | 200°C to 600°C (392°F to 1112°F) |

| Material Compatibility | HDPE, LDPE, PVC, PP, and EPDM |

| Welding Speed | Up to 20 meters per minute |

| Power Source | Electric or Diesel Generator |

| Application Areas | Landfills, Ponds, Canals, and Mining Operations |

| Operator Skill Level | Intermediate to Advanced |

| Maintenance Requirements | Regular Cleaning and Part Replacement |

Step-by-Step Process of Using a Geomembrane Welding Machine

Using a geomembrane welding machine involves a straightforward process that requires attention to detail. Start by preparing the seams where the geomembranes will be joined. The surfaces must be clean and dry. This preparation prevents contamination, which can compromise the weld quality.

Once the surfaces are ready, align the geomembrane sheets. A proper alignment ensures a uniform weld. It is crucial to monitor the temperature settings of the welding machine. Industry reports indicate that optimal temperature ranges between 400°F to 600°F (200°C to 315°C) for effective welding. Adjusting the speed is equally important. A slower speed can result in excessive melting, while too fast may lead to weak bonds.

After setting up the machine, begin the welding process. Make sure the machine moves smoothly along the seam. Operators should be aware that pressure also plays a significant role in weld integrity. An insufficient amount of pressure can lead to weak joints. According to recent studies, nearly 15% of geomembrane failures are due to improper welding techniques. Monitoring the welding operation closely helps identify any issues promptly. Geomembrane welding is a skill that requires practice and diligence for optimal results.

Geomembrane Welding Machine Usage Statistics

Applications and Benefits of Geomembrane Welding in Various Industries

Geomembrane welding is essential in many industries. It provides a reliable method for joining materials used in containment applications. With the rise of environmental protection needs, the use of geomembrane has increased. They are commonly found in landfills, mining operations, and water containment facilities.

The welding process involves heat, pressure, and time. This combination creates a strong bond between geomembranes. Proper techniques enhance durability and longevity. However, the skill level of the operator can affect the outcome. Equipment settings must be precise. Minor mistakes can lead to leaks or failures, impacting environmental safety.

In agriculture, geomembranes help with water retention. They line canals and ponds effectively. In the construction sector, they provide solutions for waterproofing basements and tunnels. Industrial sites also benefit, as geomembranes prevent contamination. Despite their advantages, challenges remain. Environmental factors can alter conditions during welding. Regular training and checks are vital for optimal performance and reliability.